Granular filtration

GRANULAR FILTRATION

Sand filter, multilayers filters sand/anthracite, dehydrated silicon dioxide filters

Suspended matters and colloidal particles are eliminated by landing on the surface of the granular mass when the water flows, through the filter bed.

The quality of the filtrate depends of the size, surface charge, geometry of suspended solids and operating parameters.

A system correctly designed and well exploited product filtrates whose SDI is less than 5 or 3 on some waters.

Benefits :

- – Suspended matters reduction (MES)

- – Water turbidity reduction (NTU)

- – Fouling index

MATERIALS USED

Filters materials most commonly used to water treatment are sand and anthracite. Optimal grain size is between 0,35 and 0,5 mm for a fine sand filter and 0,7 to 0,8 mm for anthracite.

Double layers filters (anthracite on fine sand) allow better penetration of suspended matters in the filter medium.

Which results by a more efficient filtration and decrease the cleaning frequency.

Filter layer must be thickness of 80 cm minimum.

Bilayers filters usually have 50 to 70 cm sand and 25 to 30 cm of anthracite.

FILTRATE OPTIMIZATION

Use of dehydrated silicon dioxide.

This filtration media improves the quality of filtrate and filtration speed can be increased thanks to its particular structure.

Its split edges and his irregular profile provides the dehydrated sillicon dioxide (Filter AG) a very large surface of filtration forcing water to complex water circulation.

Filtration threshold is 20 to 40 µm. Pressure drop through the filter bed is less than that of all other filter media.

This allows a penetration of suspended matter and greater accumulation between two backwashes.

The large irregular shapes of filter AG prevents the formation of caking, quickling creating a pressure drop in the first centimeters of a sand filter.

Because of its low density (400g/l) backwash flow must be controlled to allow a very good expansion of the filter bed and evacuation of the sediment.

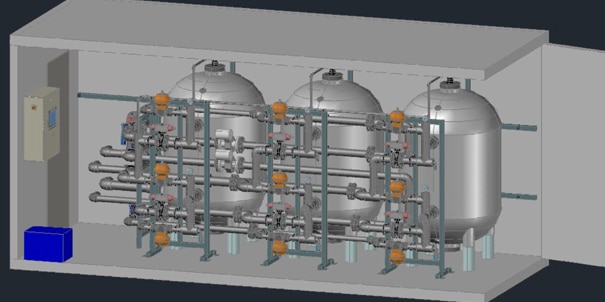

Filters tanks can be made of steel or composite.

The internal distribution of the filters is carried out with arm strainers or strainers floors.

Only the screened floor version allows air injection when operating conditions (water quality, filter media quality) require it.

CALCIUM CARBONATE FILTRATION

A low salinity water often have a relatively low Ph (below standards) and are often corrosive with a risk of damaging the metal pipes.

They cause, in some cases, dissolution of heavy metals, like leads, iron or copper which make them unfit for potable use.

It’s possible to realize neutralisation by filtration on a media composed of crushed and sieved natural calcium carbonate : calcite.

Acidic water slowly dissolves calcium carbonate until reaching a Ph which reduce corrosion phenomena. The process is self-balanced.

The reaction between the Co2 and calcite can be summarized as :

CaCO3 + Co2 + H2O à Ca2+ + 2 HCO3-

For high saline water, it will be necessary to injected pressurized Co2 upstream of the remineralizing filter.